Standard or Regular Expanded Metal offers high rigidity in a variety of sizes and weights.The angles of the diamond strands allow maximum air circulation and distribute load on the metal to supporting frames.

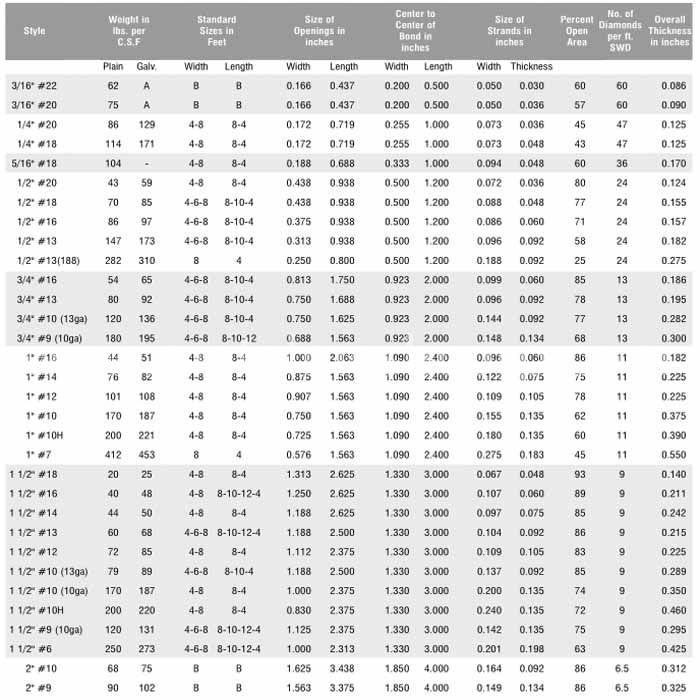

Product parameters

How to order Expanded Metal?

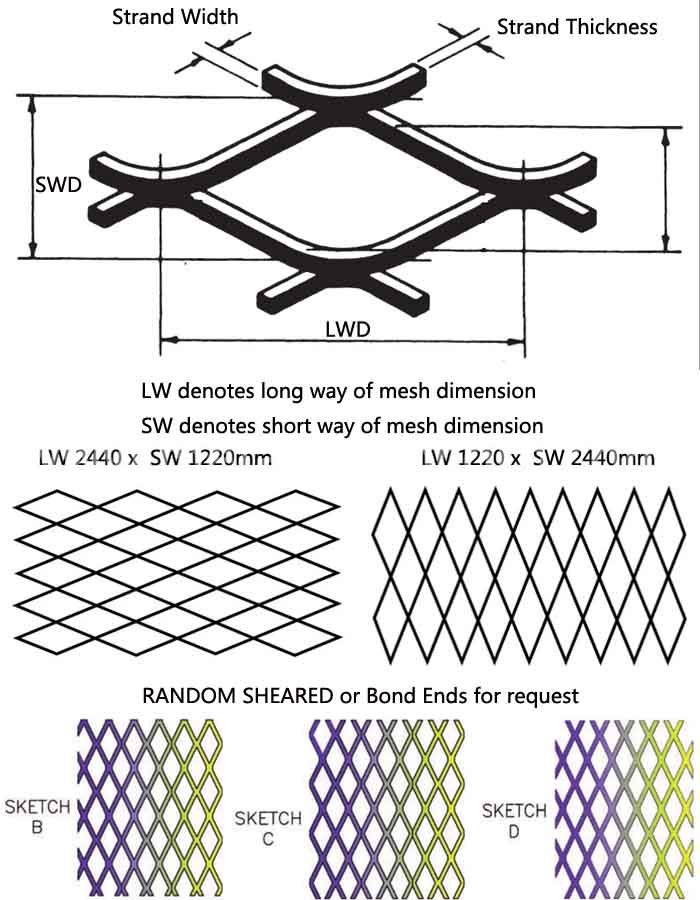

SWD – Nominal dimension, Short Way of Diamond.

LWD – Nominal dimension, Long Way of Diamond.

DESIGN SIZE – Actual dimension SWD and LWD.

Measured from a point to a corresponding point on the adjacent diamond.

STRANDS – The sides of the Expanded Metal design.

STRAND THICKNESS – Thickness of the base metal.

STRAND WIDTH – Amount of metal fed under dies to produce one strand.

STRAND THICKNESS AND WIDTH – Can be varied to create different openings. The width of the strand should equal or exceed the thickness of the base metal.

Product Features

Expanded Metal is produced from a single sheet of steel. The production process does not waste material and the cold worked ‘knuckles’ within the mesh give expanded metal some of its most important benefits.These knuckles can withstand stress and can support a greater weight than joints or welds.When galvanised to BS EN ISO 1461:1999 the heavier joints of expanded metal offer greater corrosion resistance than the smaller joints in a wire mesh or the joints in a woven mesh which can rub and wear.

Expanded Metal is a highly efficient conductor,particularly of heat and electricity.

As the mesh is formed from a continuous piece of metal there is nothing to work loose, and the material can consequently stand up better than other meshes to impact and rough treatment.

Expanded Metal does not fray, even when cut into different shapes. Often, Expanded Metal can be left unframed as its inherent strength is sufficient.

Expanding sheet steel strengthens its point load whilst utilising the steel more efficiently and economically.

The rhombic shape to the mesh and angled strand formation makes Expanded Metal an ideal reinforcing mesh for other materials.

Expanded Metal provides an anti-slip surface.

The angled strands of Expanded Metal make this type of mesh most suited to applications where the louvered effect has significant benefits (eg. Anti dazzle screens, retention of product but allowing air, water and light through or decorative work).

Scope of application

The versatility of Exanded Metal is the key to a virtually limitless variety of applications. Some of these applications include:

♦ Air and Fluid Filters

♦ EMI/RFI Shielding

♦ Battery Cells

♦ Ventilation Systems

♦ Strainers

♦ Satellite and Radar Antennas

♦ Partitions

♦ Outdoor Furniture

♦ Speaker Grills

♦ Security Walls, Ceilings, Floors, Doors

♦ Machine and Window Guards

♦ Fencing

♦ Shelving and Racks

♦ Concrete Reinforcements

♦ Walkways and Stair Treads

♦ Containers

♦ Greenhouse Benches

♦ Decorative Dividers

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap