Perforated metal sheets, also known as perforated sheets or screens, have been used for over a century or more to create patterns of holes, shapes or slots. Perforation is the process of manually pressing or stamping a sheet to form holes and slots in a given pattern. These metals are used in a variety of industries, including various fields such as construction, architecture, chemicals, food and automotive, as will be explained in detail later in the post. The metals used for this process include stainless steel, brass, aluminum, copper, galvanized steel, etc. These ready-to-use sheets are available on the market in a variety of geometries, sizes and materials. This post focuses on all the important areas of perforated metal sheets.

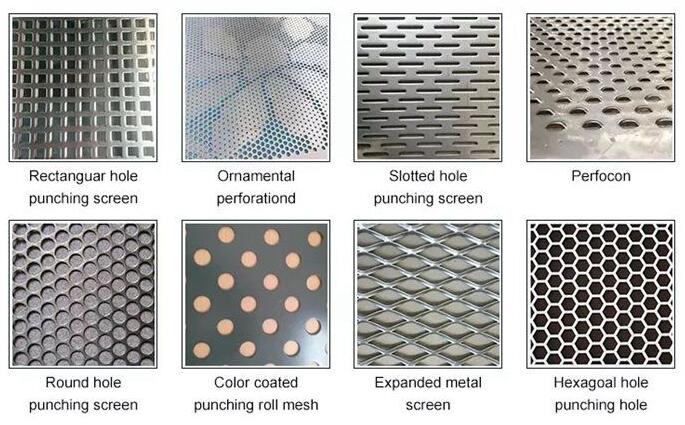

The types of perforated metal depend on their size, gauge thickness, the material used and the application area. However, there are various types of perforated metal sheets depending on the shape, including round holes, square, bar, other decorative shapes, slotted and hexagonal. There are a variety of architectural patterned metal sheets that facilitate ventilation within the building and add aesthetic appeal.

In fact, it is a good idea to keep sheet metal manual punching kits on hand, especially if you are involved in construction or architecture. Sheet metal punch kits usually include a set of tools that include about six to seven punches and die accessories, such as punches and pliers. The number of tools in a kit may vary depending on the size and brand of the kit. You can use them manually to create holes or designs in sheets for home improvement projects. These tools are versatile, lightweight and rugged.

There are many benefits to using perforated metal panels in homes, offices and other public spaces. We have listed some of them here.

▸ Ventilation and natural light: Perforated metal panels help ventilate a room while subtly allowing light to enter the room through their holes or design. Thus, their unique design protects us from direct sunlight while still allowing the room to have natural light. The holes or designs in the paper balance the flow of air and light in the room.

▸ Energy efficiency: Some buildings have perforated panels on the front. This helps save energy and reduces the use of HVAC products such as air conditioning and lighting systems during the day.

▸ Reduced noise levels: They help to reduce noise or sound levels. This is especially useful in public spaces and offices located in high-traffic areas.

▸ Slip resistance: Perforated panels have excellent slip resistance and are therefore used in wet and humid areas.

Perforated metal sheets have many applications, especially in construction and other industries. Here are a few.

▸ Construction: Perforated metal sheets are widely used as fence screens, post covers, awnings in gardens, cladding, etc.

▸ Structures: They are used as ventilation grilles, acoustic panels to reduce noise levels, such as signs, pipe guards, etc.

▸ Automotive: Perforated panels are used for engine ventilation in tractors, air filters, radiator grilles, bicycle silencers, oil filters, etc.

▸ Chemical: Perforated sheets are used as filters, mines, battery partitions, water curtains and gas purifiers, etc.

▸ Food and beverage: These sheets are used as baking trays, coffee filters, silo ventilation, fish farming, cheese molds, and grain dryers, among others.

Thus, perforated metal sheets have many applications and can be beneficial in many areas. If your application requires prefabricated and perforated metal sheets, be sure to select the correct size and material and purchase from a reliable supplier. We are one of the leading manufacturers and suppliers of sheet metal fabrication equipment for the manufacture of perforated sheet metal.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap