When you need to make this decision, the first thing you need to do is consider your application. The pattern and other features you choose for your perforated metal will affect the way you use the finished product. Do you need perforated metal to dissipate heat in an area or to soundproof a room? Perhaps you are considering a completely different feature. Learn this information before proceeding.

Before deciding on a specific metal type and thickness, you need to know the strength and stiffness required for the final product. Perforated metals are not as strong as non-perforated metals, but you can choose from several different thicknesses and materials such as aluminum, copper, brass, various steels, etc. that will help you achieve the desired structural capacity.

Thinner perforated sheets are less expensive because there is less material involved and less effort required by the manufacturer to machine them, but the low price doesn't always make them the right choice.

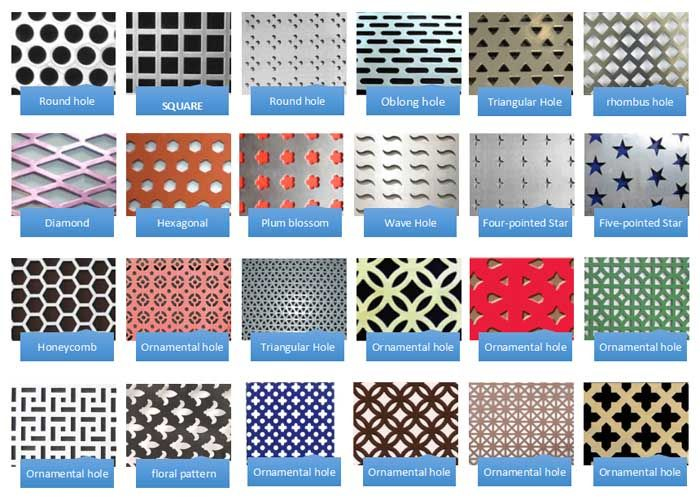

The type of holes you choose for your perforated metal will affect both functionality and appearance. Our cutting machine has the technological ability to produce some of the most common and inexpensive choices, or decorative shapes that follow:

· Round: For an easy and therefore economical shape that functions well in many applications like air conditioning and heating systems, aesthetic architectural design and more, you could choose round holes.

· Square: This pattern is a good choice if you want to get fresh air and a clear view through the finished sheet. While providing that benefit, these perforated sheets also provide a durable barrier for impact-load resistance and protection against trespassers.

· Slot: Slot holes have long rectangles with square or half-circle ends. Professionals in the manufacturing industry tend to favor these versatile shapes for applications like material screening and sorting — especially with similarly shaped materials like seeds and grains. Slot direction on the sheet is up to you.

· Ornamental / Decorative Perforations: These unique patterns include moire, Grecian and cloverleaf. They are ecstatically pleasing and functional.

All the patterns above can then be custom cut/punched for individual needs.

Once you have selected the shape of the holes in your perforated metal, it is time to choose a pattern.

The most common pattern type is a straight line, with repeating rows having the same number of holes as the previous row. Another option is a staggered layout, which allows for offset alignment from adjacent rows. Finally, and less commonly, some people choose non-standard patterns, such as spirals, stars, or circles, for unique applications or design achievements.

The pattern you choose for your perforated metal will change the strength, function, appearance, cost and time requirements of each sheet.

When you choose HEBEI METAL MESH CORP, you choose to have your metal customized by trained technicians. Expect perforations that meet and exceed your exact specifications for quality. We'll deliver a unique end product quickly to help you get the job done right. If you need help in making any decision, we will answer all your questions and provide the information you need.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap