Perforated metal sheets are made of various metal sheets as raw materials, and through modern processing technologies such as punching machines and CNC laser cutting, the sheets are regularly perforated with various holes to form a special texture. After perforation, the sheet metal can also be processed with different surface treatment.

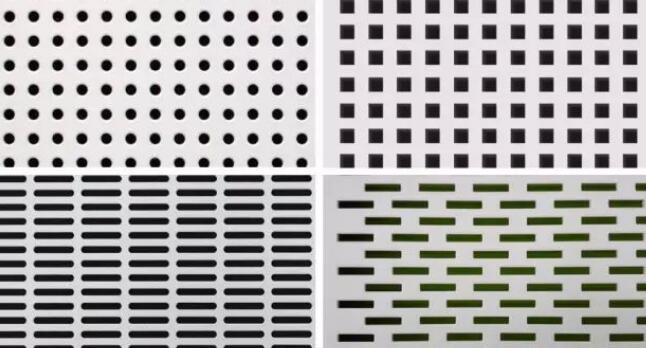

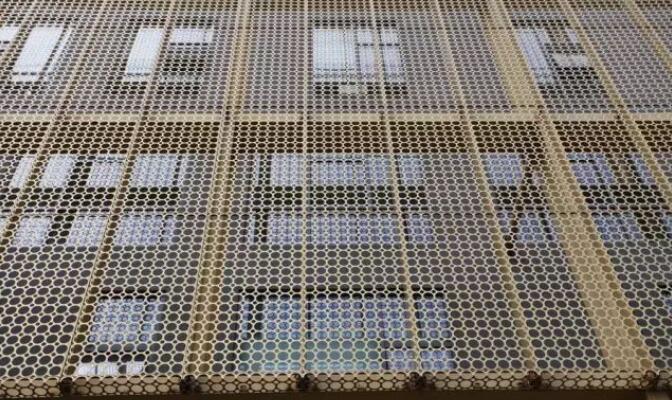

Various perforated metal sheets with different patterns

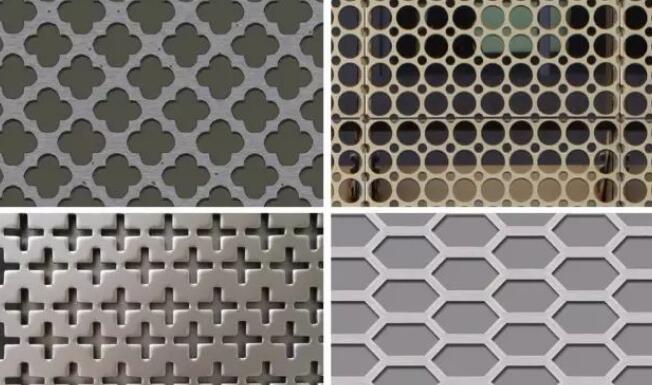

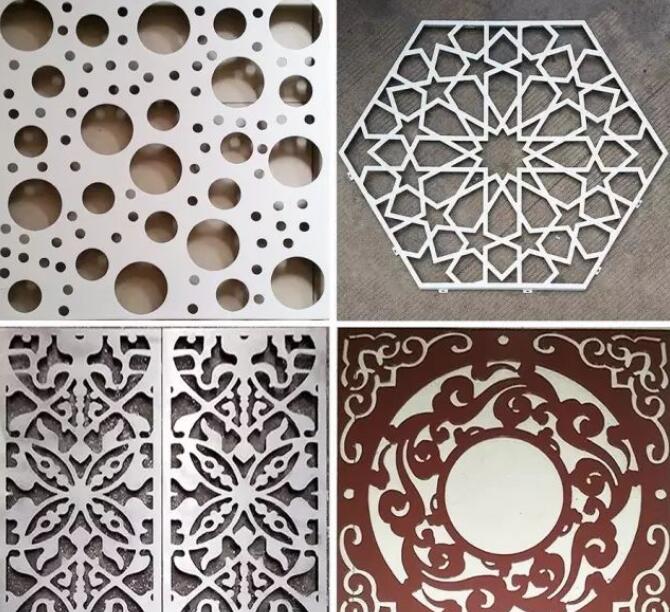

The early perforated metal plate is restricted by the punching machinery, the general hole is more regular, with the development of CNC technology and plasma, laser, waterjet and other cutting technology, perforated plate gradually break through the original restrictions, to any form of carving direction, this carved out of the metal plate is also carved metal plate.

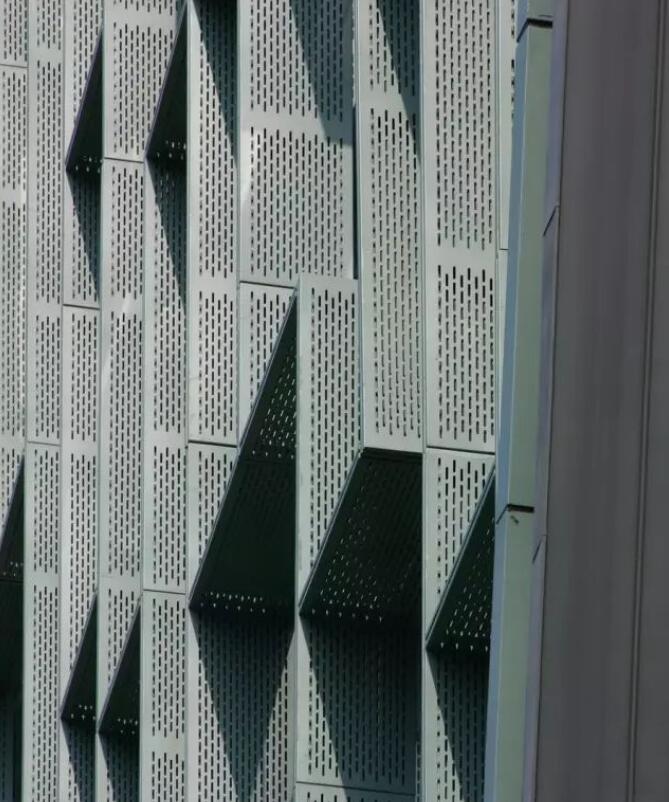

More arbitrary and free carved metal plate

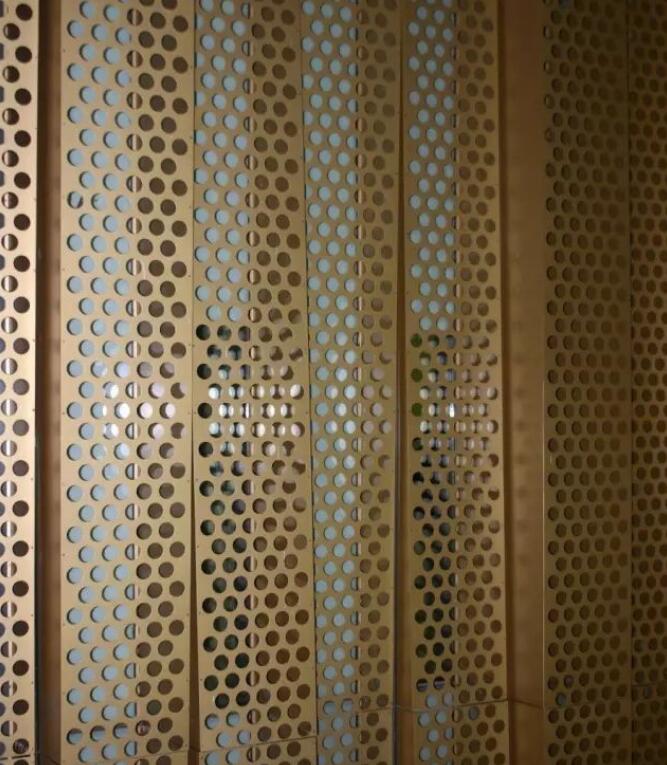

Carved metal plate exterior wall finishes

Perforated, carved metal panels are generally used for outdoor conditions when the use of better weather resistance of aluminum alloy plate, copper (alloy) plate, stainless steel plate, weathering steel plate and other plates with a certain thickness and rigidity as the original plate, the most used in the building when the perforated aluminum alloy plate.

The structure of perforated metal plate (especially flat plate) is generally similar to single-layer metal plate; when the perforation size and density are larger, i.e., the permeability is higher, the stiffness of the plate is affected and the reinforcement rib structure is needed.

Embassy of the five Nordic countries in Berlin - Embassy of Denmark

The smaller perforated metal panels have less light transmission and are more shielded from view, so they are used more as a finish material similar to traditional metal curtain walls, and are therefore designed to be openable at the corresponding interior windows.

LVMH Building, Osaka, Japan

Patterned effect with different holes

Wukesong Basketball Hall for the Beijing Olympics

The perforated metal curtain wall with undulating waves like water plants

Suzhou Bio-Nano Technology Park

The large area of perforated metal panels used for the facade covers the building as a whole, which not only ensures natural ventilation and sight lines, but also simplifies the complex façade that originally contains windows and solid walls, resulting in a stronger sense of unity and a more concise form of the building.

This method of wrapping the building with perforated panels is more suitable for the transformation of old building facades that were originally poorly designed, and attention should be paid to the control of the perforation rate to avoid affecting the need for ventilation, lighting and sight lines.

A department building of the University of Economics and Business in Vienna, Austria - perforated metal panels as sunshade windows and doors

Beijing Digital Information Publishing Center

Fixed sunshade for the east-west direction of the building

Metal plates with large holes and perforation rates have poor stiffness, and can be rolled into broken panels with different section forms to improve panel stiffness, which objectively also creates a corrugated panel effect different from that of flat panels.

For more valuable metal materials (such as copper), thin plates are often used to save metal consumption for perforation processing. These relatively thin perforated metal plates also have poor stiffness and can also be used in the form of broken panels to improve panel stiffness.

Pressed (bending) perforated metal curtain wall construction is basically similar to the common pressed metal plate (wave plate).

In addition, the use of metal tensile properties, less rigid perforated metal plate can also be used similar to the construction of metal mesh around the tension fixed.

Common Audi 4S store pressed perforated metal plate

Lucerne International Cultural Conference Center, Switzerland

Copper green corrugated perforated copper sheets as a material for covering large areas of walls.

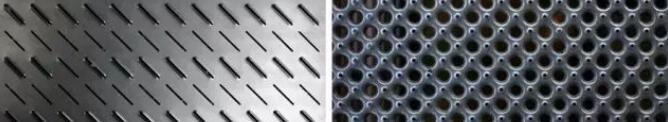

Perforated thick steel plate combined with convex and concave treatment can produce a certain friction, often used in some industrial and civil buildings for flooring and stair treads, this material can make people feel more industrial.

Two types of perforated+convex steel plates for flooring

Perforated steel plate for stair treads

Perforated metal sheets are often used indoors as wall and ceiling decorative materials, and there are many different types. The perforations and the sound-absorbing wool attached to the back of the sheet can improve the sound effect in the room.

Perforated metal panels for indoor conditions, the metal weathering, strength requirements are not as high as outdoor, ordinary 1mm below the galvanized steel, color coated steel for the substrate of the decorative panels in the ceiling materials are more common, but due to the perforated cut corrosion-resistant weak links, this metal sheet should be avoided for the bathroom and other wet places, perforated aluminum panels are more reliable.

Common perforated metal sheets (sound-absorbing panels) indoors

The processing of perforated and carved metal panels is already a relatively simple technology in China. Different hole types, sizes, patterns, perforation rates, materials and structures will profoundly affect the image of the building. How to design the perforated metal panels in the building to be more reasonable and beautiful depends more on the architect's skills.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap