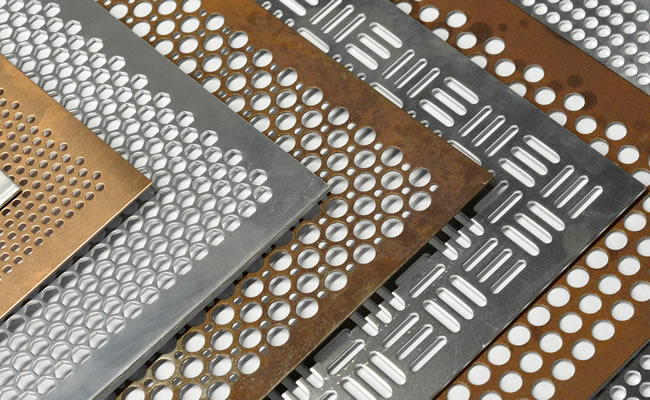

The production of perforated metal, which is sheet metal that includes holes or ports generated by punching or pushing, has actually been a necessary manufacturing and fabrication process because the mid-19th century. That's when the mining industry utilized a primitive version of the technique to create screens utilized for purification.

The perforated metal process has come a long way because the developmental years of the Industrial Revolution. Nowadays, it is possible to generate a wide variety of perforated metal items much faster and also extra efficiently than ever. The improvements are the outcome of the development of a number of manufacture techniques as well as devices for many years, consisting of:

► Laser opening: The development of laser-based innovation has actually resulted in the development of a laser perforated metal process. Several individuals favor this strategy over even more conventional mechanical perforation methods because of its faster speed, raised accuracy as well as boosted hole dimension uniformity. On the downside, laser perforation is frequently extra expensive than various other procedures, as it normally needs the purchase of specially developed roll slitting makers. Besides being cost-prohibitive for some business, this tools is much more intricate and also includes extra operator training.

► Perforation rollers: Probably one of the most common perforated metal process used today is the use of specifically designed rollers geared up with pins or needles. The outcroppings are made from products such as steel, aluminum or perhaps plastic. Manufacturers can fabricate the rollers in tailored setups for details applications. The pins or needles can be used while chilly or warmed to create the desired outcome. A hot needle will certainly create a strengthened ring around the opening for additional toughness and stability.

► Die and also punch perforation: The die and punch perforated metal process is frequently the very best option when working with thicker metals. This method entails pressing a sheet of needles versus the metal surface area, creating them to pass through the material. The process generates chads that are shaved off after pushing to develop a smooth surface. Fabricators shape the die and also punch to the wanted arrangement, leading to an extremely exact finished item. The top quality of die as well as punch perforation commonly equates to that of the moving process.

HEBEI METAL MESH CORP has the facilities, tools and expertise to execute the current, most innovative perforated metal processes. With greater than thirty years of metal fabrication experience, you can trust us to supply premium perforated metal items that will exceed your assumptions. We're known for our quick job conclusion times and also our ability to meet the tightest deadlines-- while maintaining within spending plan criteria.

Call us for more information about our perforated metal process as well as obtain a no-obligation project quote today.

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap