We developed an advanced production line - etching perforated metal , which creates chemically micronic flow channels on the surface of metal panel, to enable precision rate ranging from 30 μm to 100 μm absolutely.Minist hole can be 0.05mm hole dia.

Product parameters

This etched plates can be used as fiber filter, textile filter and other filters in food and beverage industrial such as a coffee filter to ensure its mellow smooth taste. The small hole also makes the plate prevent unwanted things out, such as insects, even dust.

Specifications for perforated metal mesh:

Material | Stainless steel and colled rolled steel | |||

Thickness | 0.1mm--1mm | Aperture | 0.03-5mm | |

Size | max 500x500mm | |||

Hole shape | Rectangular, square, Diamond , round,Triangular,Louver, irregular hole | |||

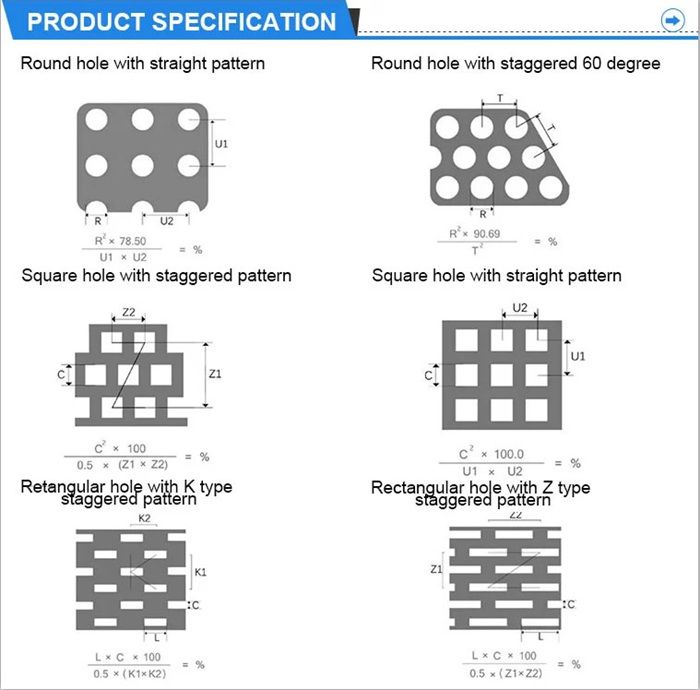

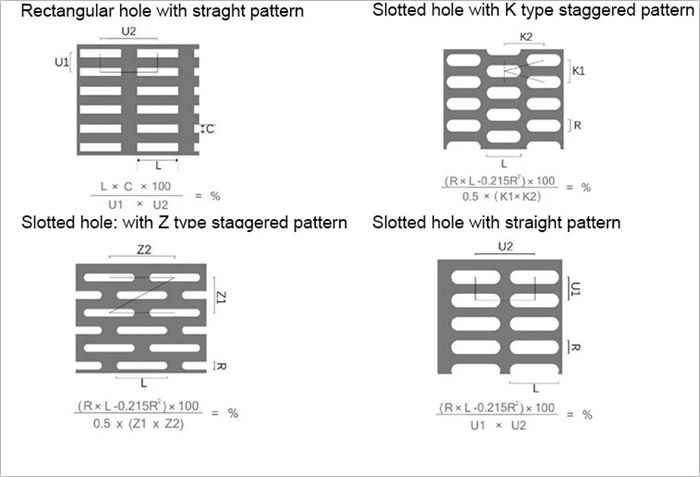

Hole arrangement | 90°staggered,45°staggered, 60°staggered , 90°straight | |||

Surface treatment | polished or mill finish | |||

Advantages | Light weight,durable application,good sound absorption,various hole design | |||

Application | petroleum, chemical,food,pharmaceutical filtration,filter board,filter tube,electronic, optical, spring and mobile phone parts etc. | |||

Product Features

Chemical Etching Perforated Sheet Features:

Super fine holes for high precision filtration.

No welding, no burs, no broken points and no plugging holes ensure the most reliable filtration.

Available in thousands of different plate shapes and hole patterns.

No need open tooling or moulding for low cost.

High tolerance ± 0.01 mm.

Welcome to email us your enquiry on Etching perforated metal, referring to below detail specifications:

| Material | Alum sheet, alum ally sheet, carbon steel,galvanized steel, stainless steel, |

| Thickness | 0.1mm-10mm |

| Hole size x pitch | Customized as request |

| Sheet size | Max width 1800mm, Max length 4000mm |

Scope of application

We carry Chemical Etching Perforated Sheet in a wide array of hole shapes, sizes, gauges, and material types. This makes perforated metal ideal for many applications ranging from metal screens to metal signage. The most common applications for perforated metal include:

earphone speaker

petroleum,

chemical,

pharmaceutical filtration,

filter board,

filter tube,

electronic,

spring and mobile phone parts

Copyright © HEBEI METAL MESH CORP All Rights Reserved Sitemap